Electroless nickel-silicon carbide composite plating plays an active part as a replacement for hard chromium plating, by making use of the features of electroless plating (plating of non-conductive materials, such as resins and ceramics, and also uniform plating of complex-shaped materials) and the features of composite plating (composite plating of hard nickel-phosphorus plated metals and wear-resistant fine particles, like silicon carbide).

| Type of plating | Features (characteristic value) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Electroless nickel-silicon carbide composite plating | - On electroless nickel-phosphorus plating films, which is a matrix metal of composite plating, the bonding force between the matrix metal and silicon carbide particles is strengthened by heat treatment, and the matrix itself hardens. Furthermore, the composite effect with the silicon carbide particles enables a low friction coefficient, and improves the life of sliding parts dramatically.

|

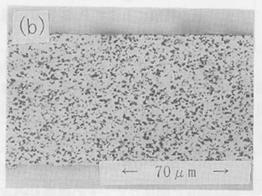

Cross-section SEM photo of composite plating film