Engineering plastics have taken root as the generic name of plastics excelling in thermal resistance and mechanical characteristics. From the aspect of performance, it is defined as being 500kgf/cm2 in tensile strength, 20,000kgf/cm2 in bending elasticity, and 100°C or higher in long-term thermal resistance. Engineering plastics with higher thermal resistance are called super engineering plastics. The purposes of plating these plastics include [1] weight reduction and cost reduction [2] ease of molding and degree of freedom in product design, [3] upscale appearance of products by metal texture, [4] improvement of hardness and frictional damage resistance, [5] giving electrical conductivity, and [6] improvement of gas barrier properties, and [7] improvement of thermal resistance, weather resistance and contamination resistance.

| Category | Type (Crystalline resins are marked with a circle (○).) |

|---|---|

| Thermoplastic resins | [General-purpose resins] long-term heat-proof temperature 50°C - 100°C |

| Thermosetting resins | alkyd resin, epoxy resin (EP), diallyl phthalate resin (PDAP), silicone resin (SI), phenol resin (PF), ○ unsaturated polyester resin (UP), polyurethane (PU), melamine resin (MF), urea resin (UF) |

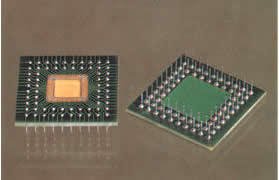

Plating for special engineering plastic

(molded printed circuit board)