Bumps are protrusion electrodes.

Bumps convenient for electrical connections are formed on aluminum electrodes of semiconductor chips used for TAB and flip chip bonding.

| Type | Features & uses |

|---|---|

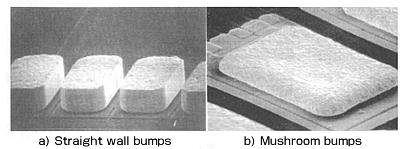

| Bump formation by electroplating | - Costly with large-scale facilities - Complex process - Types of bump metals: Gold plating, solder plating, etc. - For narrow pitches: Straight wall bumps are best suited. - Suitable for microbumps. - Uniformity of thickness of bump films is dependent on current distribution. |

| Bump formation by electroless plating | - Low facility cost - Simple process - Types of bump metals: Limited to nickel-gold plating - Unsuitable for narrow pitches (possible with resist mask) - Unsuitable for microbumps (possible with resist mask) - Uniformity of thickness of bump films is good. |

(From “Denshi Buhin no Mekki Gijutsu” by Hidehiko Enomoto, Tsuneshi Nakamura; Nikkan Kogyo Shimbun Ltd.)

Gold bumps by electroplating

(From “Denshi Buhin no Mekki Gijutsu” by Hidehiko Enomoto,

et al.; Nikkan Kogyo Shimbun Ltd.)

Types of plating