Plating the film thickness of which is smaller than 5μm (approximately 0.1 - 0.3μm) is called decorative chromium plating, and that 5μm or larger is called industrial chromium plating or hard chromium plating.

Although most chromium plating comes out of a hexavalent chromium bath, from the perspective of environmental harmony, this is moving toward trivalent chromium or chromium-free plating.

| Type of plating | Features | Characteristic value |

|---|---|---|

| Industrial (hard) chromium plating (hexavalent chromium bath) |

- In order to improve wear resistance, various materials are plated as thick as 5 to hundreds of millimeters. Since microcracks or micropores specific to chromium plating are formed, lubricity is enhanced by using them for oil retention. | - Hardness Hv = 800 - 1000 |

| Superhard thermal-resistant chromium plating (Cr-C alloy plating) |

- Plating is structurally amorphous as is. When it is heat-treated, the hardness is Hv1800. - Having excellent thermal resistance and wear resistance, it is applied to molds. |

- Hv 1800、 |

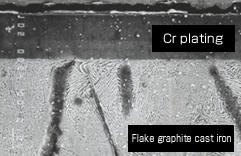

Cross-section SEM photo of hard chromium plating

on flake graphite cast iron